The Power of a Digital 3D Twin in Agriculture

Technology innovation can come from anywhere. With artificial intelligence (AI) and Augmented Reality (AR) becoming widely used in all industries around the globe, it’s no shock that agriculture would also adopt new, smart tools to help customers make better and more informed decisions based on their operation’s needs.

The Power of a Digital 3D Twin in Agriculture

Technology innovation can come from anywhere. With artificial intelligence (AI) and Augmented Reality (AR) becoming widely used in all industries around the globe, it’s no shock that agriculture would also adopt new, smart tools to help customers make better and more informed decisions based on their operation’s needs.Agriculture has been on the frontier for new, innovative developments to increase sustainable food production to help feed the growing population. With this in mind, we have been on the forefront of incorporating smart technology to improve productivity, profitability, and traceability. As the global Learning and Development director for AGCO’s Grain and Protein brands, I am lucky to travel and learn from our internal teams and dealers about the challenges farmers face globally. Recently, discussions have focused on how to use technology to transfer knowledge faster and provide a more dynamic learning experience. Specifically, I have been asked about technology use in three main areas.

- Sales

- How can we do a better job of helping our customers visualize their new grain, livestock or fertilizer facility so their design is the correct solution for their specific operation?

- Training

- How can we train more effectively when it is impossible to bring large equipment into a classroom and traveling to an existing site is challenging because of safety and biosecurity concerns?

- Installation and Repair

- Can we reduce install and repair time on our equipment by using existing 3D CAD assets to deliver animated installation and repair instructions? Can this be done on site, as they are standing next to the physical piece of equipment?

In February of 2018, the AGCO Acceleration Center launched at the University of Illinois Research Park giving AGCO access to thought leaders in emerging technologies such as computer science and agriculture production. With strategic partnerships like the University of Illinois, we are able to provide high tech solutions to not only our dealers and producers, but also provide solutions to food production and storage globally.

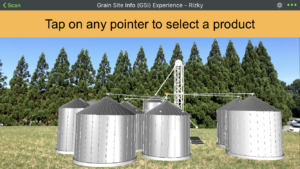

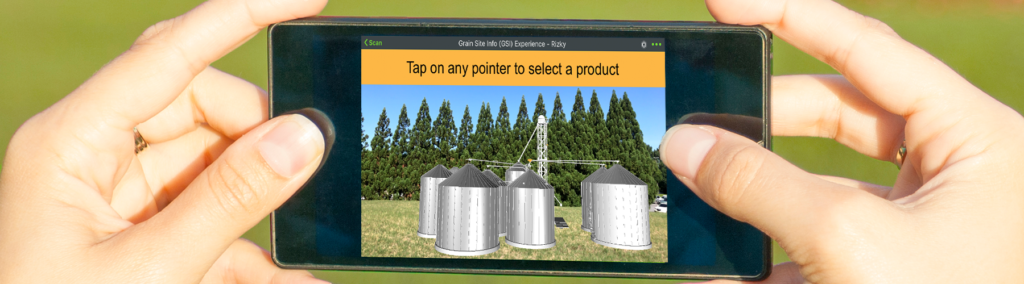

I have utilized the AGCO Acceleration Center to explore the use of Augmented Reality (AR) technology (which layers digital assets and data on top the real, physical world) to help find these solutions. What I have found is that the creation and use of this “Digital 3D Twin” – or the combined physical grain or livestock system and AR technology – has enormous potential to provide customized solutions, dramatically enhance knowledge transfer, and potentially increase system efficiency for our grain, seed and livestock producers.

Let me explain how.

Sales

Currently, blueprints or 3D computer aided design (CAD) drawings are used to help our customers make system design and equipment selection decisions. While better drawn by hand, this technology limits the ease of which sizing, placement and selection of the equipment is accomplished. And, unlike a tractor or combine, you can’t demo a grain silo or livestock barn “in the field.” However, through the use of AR, we are now able to “demo” a “Digital 3D Twin” of the physical system on a specific site. A customer can walk that facility on their own farm, with the “Twin” placed next to their existing grain bins or livestock barns, allowing a walk-through of the proposed investment. Through AR, customers can decide whether it is exactly what they want and allows them to make better buying decisions for their operation.

Training, Service and Installation

Once finalized, the “Digital 3D Twin” of their system becomes a digital asset that can be used for training to insure the new system is installed and repaired correctly. We are actively creating a library of AR training tools that can be linked to the specific equipment in each digital twin. While manuals and in-class training will not go away soon, we are using AR to enhance classroom training experiences and to provide training tools that can be taken to sites and utilized to reinforce skills. We are confident that using AR to provide step-by-step 3D animated installation or repair instructions will help systems get installed quicker and breakdowns repaired faster.

The Future

As we imagine the future, we see the “Digital 3D Twin” connected to a specific system’s data, and AR allowing the visualization of that data next to or on top of physical equipment. As you walk past a bin of a large grain system, imagine being able to see the moisture levels of grain inside the bin, in 3D. Adjusting the fan speed or identifying the specific location of wet spots to help prevent grain spoilage would be simple. Imagine having a beacon direct you to the specific conveyor bearing that is sending an alarm, then having the ability to visualize maintenance data, identify likely causes of the alarm, search for part numbers and availability, and access 3D-animated repair instructions.

In a livestock facility, imagine walking a barn and seeing floating gauges that provide real-time temperature, humidity, air-quality and air speed data for that specific location. Imagine being able to visualize individual equipment performance and even individual animal data that can then be used to make adjustments to maximize equipment performance and assist in animal care.

Digital Transformation

Beyond Grain and Protein, AGCO is leveraging smart visualization tools for customers, dealers and employees all around the globe, empowering users to make more informed decisions. To give a few examples:

- Google Glass, and augmented and assisted reality solution, is being utilized to assist with quality control and other key assembly processes and to access manuals and assembly instructions in our Jackson, Minnesota facility, which helps with increasing productivity and improve product quality.

- Other smart offerings like AGCO Smart Connect, a machine visualization offering, provides users the ability to enable machine performance adjustments, receive data to help make decisions in real-time, and adjust settings through a smart device.

- Users can also utilize another smart solution, AGCO Connect, to receive alerts on machine performance, service scheduling, and connect all AGCO machines under one platform giving maximum machine visualization capabilities and real-time data at users’ fingertips.

In conclusion

Innovations lead to growth and opportunities. Data visualization and AR are powerful, emerging technologies that have the potential to provide high tech solutions to farmers feeding our world. AGCO’s presence at the University of Illinois Research Park provides us with a unique opportunity to leverage world class thought leaders in computer science and production agriculture to identify additional emerging technologies that will add value for the businesses of our dealers and customers. We can help customers make better buying decisions and support our dealers by providing better training to assist them with installing and repairing our equipment. Ultimately, combining the Digital 3D Twin with data to create smart systems and smart buildings will allow farmers to visualize and make better operating decisions for their operations, increasing farm income and efficiency.

To learn more about AGCO’s presence at the University of Illinois at Urbana-Champaign, visit https://www.agcoaccelerationcenter.com/.

To learn more about AGCO’s Fuse® smart farming portfolio, visit https://www.fusesmartfarming.com/ or contact your local dealer.

Written by: Lance Brown

Lance Brown is global Learning and Development director for AGCO’s Grain and Protein brands. Connect with Lance on LinkedIn.